توضیحات محصول

تحت عملکرد ترانسفورماتور، دستگاه جوشکاری لب به لب میله فولادی ما از منبع تغذیه اصلی استاندارد برای کاهش ولتاژ و افزایش جریان الکتریکی استفاده می کند. این ولتاژ پایین، جریان بالا از الکترود به نقطه اتصال دو قطعه کار منتقل می شود. در نقطه اتصال، مقاومت قطعه کار باعث ایجاد دمای بالا می شود و باعث می شود فلز به حالت مذاب برسد. این فرآیند امکان جوشکاری دقیق دو قطعه کار را فراهم می کند. به عنوان تولیدکنندگان حرفه ای دستگاه جوشکاری لب به لب میله فولادی، ما توانایی های فناوری تولید قوی را حفظ می کنیم.

سیستم کنترل جوشکاری هوشمند

قادر به انتخاب منابع تغذیه AC یا MF DC. کنترلر امکان ذخیره مدل های جوشکاری مختلف برای مواد و ضخامت های سیم مختلف را فراهم می کند.

الکترود جوشکاری

طراحی شده برای ایجاد شیارهای متعدد روی الکترودها، که امکان جوشکاری یک مجموعه الکترود را برای قطرهای سیم مختلف فراهم می کند.

قالب های جوشکاری ویژه سفارشی

ما قالب های مناسب را با توجه به نیازهای خاص جوشکاری لب به لب محصول پردازش و تولید می کنیم و فرآیندهای کاری شما را ساده می کنیم.

بازوی بارگیری و تخلیه خودکار

دستگاه های جوشکاری لب به لب ما می توانند به بازوهای بارگیری و تخلیه خودکار مجهز شوند و امکان ادغام با دستگاه های خمشی 2D/3D را برای فرآیندهای شکل دهی و جوشکاری کاملاً خودکار فراهم می کنند.

کاربرد و نمونه ها

ما خدمات سفارشی جامع ارائه می دهیم. مهندسان ما در مورد نیازهای جوشکاری خاص شما بحث خواهند کرد و پیشنهادات فنی مناسب را بر اساس نمونه ها یا نقشه های شما توسعه خواهند داد.

کاربرد

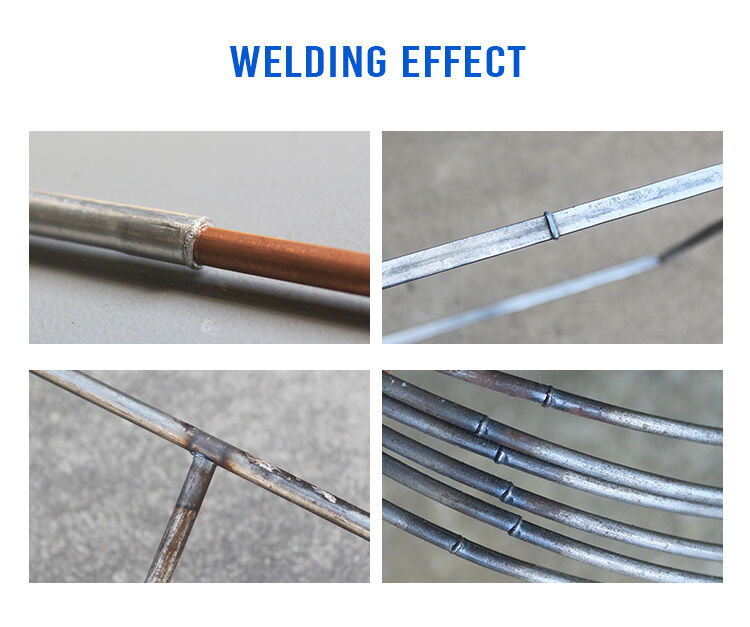

مناسب برای جوشکاری انتهایی فولاد کربنی، مس، آلومینیوم، فولاد ضد زنگ، فولاد آلیاژی و سایر مواد از جمله سیم، میله و لوله.

تجهیزات خط تولید قفسه سیم

ما دستگاه های خط تولید تمام اتوماتیک یا نیمه اتوماتیک کاملی را برای قفسه های سیم یخچال طراحی می کنیم. نقشه های دقیق محصول و الزامات راندمان را ارائه دهید و تیم مهندسی ما پیشنهادات سفارشی را آماده خواهد کرد.

دستگاه صاف کردن و برش سیم

این دستگاه سیم گرد را به سیم تخت پردازش می کند، به طور خودکار سیم گرد را تغذیه می کند و آن را به طول های مورد نیاز برش می دهد. معمولاً کویل های سیم 8 میلی متری را به نوارهای سیم تخت 12x3 میلی متری پردازش می کند.

دستگاه صاف کردن و برش سیم با سرعت بالا

امکان تولید انبوه سیم های 2 میلی متری تا 4 میلی متری را فراهم می کند. با سرعت تقریباً 5 برابر سرعت دستگاه های برش سیم استاندارد کار می کند، که به طور قابل توجهی نرخ تولید را افزایش می دهد و هزینه های نیروی کار را کاهش می دهد.

دستگاه خم کن قاب سیم

سیم های تخت یا گرد را به قاب های سیم مربع شکل خم می کند. قادر به خم کردن چندین سیم به طور همزمان برای افزایش نرخ تولید.

دستگاه جوشکاری لب به لب قاب سیم

تعداد سرهای جوشکاری به عرض جوشکاری مش بستگی دارد. سرهای جوشکاری مختلف را می توان با برنامه های جوشکاری و جریان های جداگانه برنامه ریزی کرد.

دستگاه دو T-Butt قاب سیم

میله های متقاطع قفسه های سیم را به قاب های سیم جوش می دهد. طراحی دو سر، نرخ تولید را با عملکرد آسان افزایش می دهد. ما همچنین برنامه های جابجایی و جوشکاری خودکار را طراحی می کنیم.

دستگاه اصلاح لبه سیم

پس از جوشکاری، این دستگاه اصلاح لبه های سیم را از قاب های سیم برش می دهد و سطوح تمیز و صاف را تضمین می کند.

دستگاه خم کن دسته سیم 2D

دسته های سیم را برای سیم های 2-6 میلی متری خم می کند. قادر به ایجاد اشکال مختلف سیم بدون نیاز به تغییر قالب.

دستگاه خم کن سیم 3D

سیم ها را به شکل های سه بعدی برای سیم های 2-6 میلی متری یا 3-8 میلی متری خم می کند. اشکال سیم سه بعدی پیچیده را بدون تغییر قالب ایجاد می کند.

بسته بندی و تحویل

تیم خدمات حرفه ای

در طول سال ها، Hwashi متخصصان با استعداد، متعهد و نوآور را پرورش داده است. ما یک تیم متخصص با تجربه غنی در مهندسی برق، طراحی مکانیکی و فناوری جوشکاری داریم.

از زمان تأسیس خود در 22 سال پیش، Hwashi Technology به مشتریان در سراسر جهان خدمات ارائه داده است، در بیش از 100 نمایشگاه شرکت کرده و به بیش از 8000 مشتری خدمات ارائه داده است.

سوالات متداول

سؤال 1: قیمت دستگاه شما چقدر است؟

دستگاه های ما با توجه به نیازهای شما سفارشی می شوند. برای دریافت قیمت مناسب، لطفاً موارد زیر را ارائه دهید: جنس و ضخامت محصول شما، حداقل و حداکثر اندازه محصول، موقعیت های جوشکاری، سطح اتوماسیون مورد نظر و نقشه های دقیق محصول برای پیشنهادات فنی.

سؤال 2: دوره گارانتی دستگاه شما چقدر است؟

گارانتی استاندارد یک سال پس از حمل و نقل است. دوره های گارانتی تمدید شده با هزینه اضافی در دسترس هستند.

سؤال 3: اگر دستگاه من در طول دوره گارانتی آسیب ببیند چه می شود؟

مهندسان ما تشخیص مشکل آنلاین را ارائه می دهند. در طول گارانتی، ما قطعات آسیب دیده را به صورت رایگان تعویض می کنیم. اگر مشکلات ادامه داشت، ما مهندسان را برای حل مشکل به کارخانه شما می فرستیم.

سؤال 4: زمان تحویل دستگاه شما چقدر است؟

دستگاه های استاندارد معمولاً ظرف هفت روز پس از پرداخت ارسال می شوند. دستگاه های سفارشی به 30-90 روز برای تکمیل نیاز دارند.

سؤال 5: آیا می توانیم نمونه هایی را برای آزمایش جوشکاری ارسال کنیم؟

بله. ما آزمایش های جوشکاری را انجام می دهیم و عکس/فیلم ارائه می دهیم. ما می توانیم نمونه های آزمایش شده را برای تأیید کیفیت شما برگردانیم.

سؤال 6: آیا می توانید نقشه های دستگاه و پیشنهادات فنی ارائه دهید؟

بله. پس از دریافت الزامات و نقشه ها، ما پیشنهادات فنی را با نقشه های مفهومی ارائه می دهیم. نقشه های طراحی دقیق قبل از تولید برای تأیید ارائه می شود.

سؤال 7: شرایط پرداخت شما چیست؟

ما T/T، L/C، Western Union و Alibaba Trade Assurance را می پذیریم. ما Alibaba Trade Assurance را برای محافظت از خریدار توصیه می کنیم.

سؤال 8: چگونه دستگاه را نصب کنیم؟

دستگاه های ساده شامل دفترچه راهنمای انگلیسی، فیلم های عملیاتی و آموزش آنلاین هستند. دستگاه های پیچیده شامل خدمات نصب مهندس با هزینه اضافی هستند.

پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!  پیام شما باید بین 20 تا 3000 کاراکتر باشد!

پیام شما باید بین 20 تا 3000 کاراکتر باشد! لطفا ایمیل خود را چک کنید!

لطفا ایمیل خود را چک کنید!